There are several essential components to the biological and chemical processes of life. On a cellular level, there are certain building blocks or compounds that, as their name implies, construct the framework of life. When these substances are combined with other substances, they serve an essential functional purpose.

Thanks to molecular research and biochemistry advancements, it is now possible to produce or combine chemicals in a lab and use them for diverse purposes in medicine, industry, pharmaceuticals, etc.

What is Peptide Synthesis?

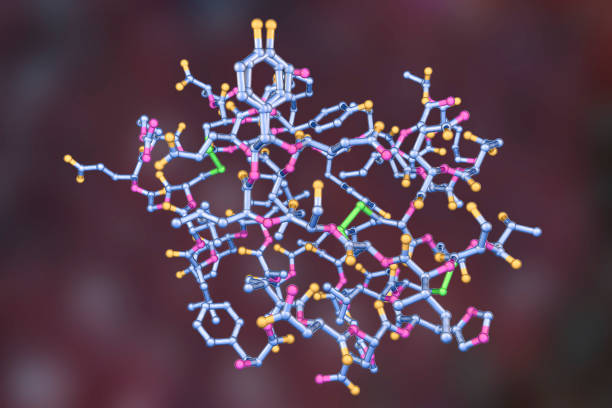

Peptides are created by assembling a chain of amino acids, as was previously described. The carboxylic acid of one amino acid joins the amine group of another acid during the manufacturing process. Every amino acid has a particular functional group, the R group, which gives them individuality.

This functional R group often determines a peptide’s general shape, structure, and property. We must first comprehend the function of amino acids, mainly when they are employed to synthesize peptides, to comprehend the complexities of peptide formation fully.

The amine group of amino acids must be sufficiently protected during synthesis to prevent unintended reactions. To accomplish this, a substance known as FMOC is used.

However, the FMOC from the side of the amine group needs to be eliminated before the attachment between the two amino acids is finished. You can maintain the FMOC on one side of the amino acid to prevent it from connecting with itself. Now’s discuss some of the prominent benefits of peptide synthesis.

Easy Modification of Amino Acids

Peptide synthesis involves adding protected amino acid derivatives to a growing peptide chain immobilized in a solid phase. This method makes modifying the amino acids within a peptide region easy.

It can also help simplify analog synthesis, providing opportunities to synthesize peptides. The improved safety profile of solid-phase peptide synthesis has allowed inexperienced chemists to undertake peptide synthesis efforts easily.

The process starts with immobilizing an appropriately protected amino acid to a linker-bound polystyrene-based resin. The peptide elongation is achieved by the deprotection of the leading chain group followed by the coupling of the next appropriately protected amino acids. This deprotection is essential to secure high-quality products during protein synthesis.

Easy purification

It’s possible to purify peptides with different physicochemical properties. The minimum requirement of peptide purity depends on your application and essay. However, since the most recommended purity is over 90%, you need a scheme that can make it easy to purify the peptides in large quantities.

Solid-phase peptide synthesis has more advantages over solution-phase protein services when purifying large amounts of peptides.

You can quickly purify the peptides by preparative or semi-preparative HPLC. This purification is quick as it considers factors like the gradient and flow rate as well as the sequence of the peptide. Compared to the liquid phase peptide synthesis scheme, the solid phase peptide synthesis uses reverse phase chromatography that removes all impurities.

Rapid generation of linear peptide intermediate

The method is superior when comparing the solution phase to a solid phase route in peptide synthesis. The solution phase approach is tedious and involves the cyclization of a ridged heterocyclic precursor, while the SPPS involves rapidly generating a flexible linear peptide.

The definition of a linear precursor involves a modified reaction that starts with an alanine residue attached to a resin. Sequential coupling of residues and cleavage generates a peptide precursor.

One of the critical requirements of regenerative biomaterials is that they support the in-growth and proliferation of endogenous cells. Solid-phase peptide synthesis is the best approach to achieving rapid tissue regeneration. It helps synthesize peptides rapidly using common reagents to achieve synthetic peptide coupling.

Precedent in the synthesis of large peptides

We can synthesize peptides using a solid phase to form a large macrocycle. This peptide synthesis is the best alternative to using the liquid phase when synthesizing peptides in high amounts.

It offers a simple option for substituting serines for cysteines. The approach applies in different processes that allow for the high throughput production of peptides. Technological advancement makes this method possible to mass-produce peptides in the laboratory.

It’s the best method to reduce the adverse effects on peptide synthesis and facilitate large-scale peptide synthesis. Usually, incomplete deprotection results in truncated or deletion sequences that impact the process.

Efficient synthesis of customized peptides

Peptide synthesis involves adding protected amino acid derivatives to the growing peptide chain immobilized in a solid phase. This scheme is popular because of its improved chemical stability and enhanced resistance to in situ enzymes. It makes it easy to synthesize customized peptides while resisting degradation efficiently.

It has also revolutionized synthetic accessibility to the chemist. The strategy allows creativity and imagination to prevent undesirable side effects during peptide synthesis. It also makes it easy to perform convergent synthesis that involves analyzing peptides into sequences and linking them to larger molecules.

Conclusion

Researchers have widely used peptide synthesis in research studies. The solid phase peptide synthesis protocol uses the widely used FMOC strategy that activates carboxyl groups.

Compared to a solution phase, the SPPS is superior in several ways. Its ability to synthesize peptides to high purity and on a large scale has revolutionized research and allowed the development of a broader range of therapeutic agents.

However, the solid phase peptide synthesis is relatively labor-intensive. There are some additional steps required in the manufacturing process.